Stent Skirt

the problem: Paravalvular Leakage

Our solution: the Stent skirt

Technical Summary of Stent Components:

Stent Skirt- Passive skirt seal

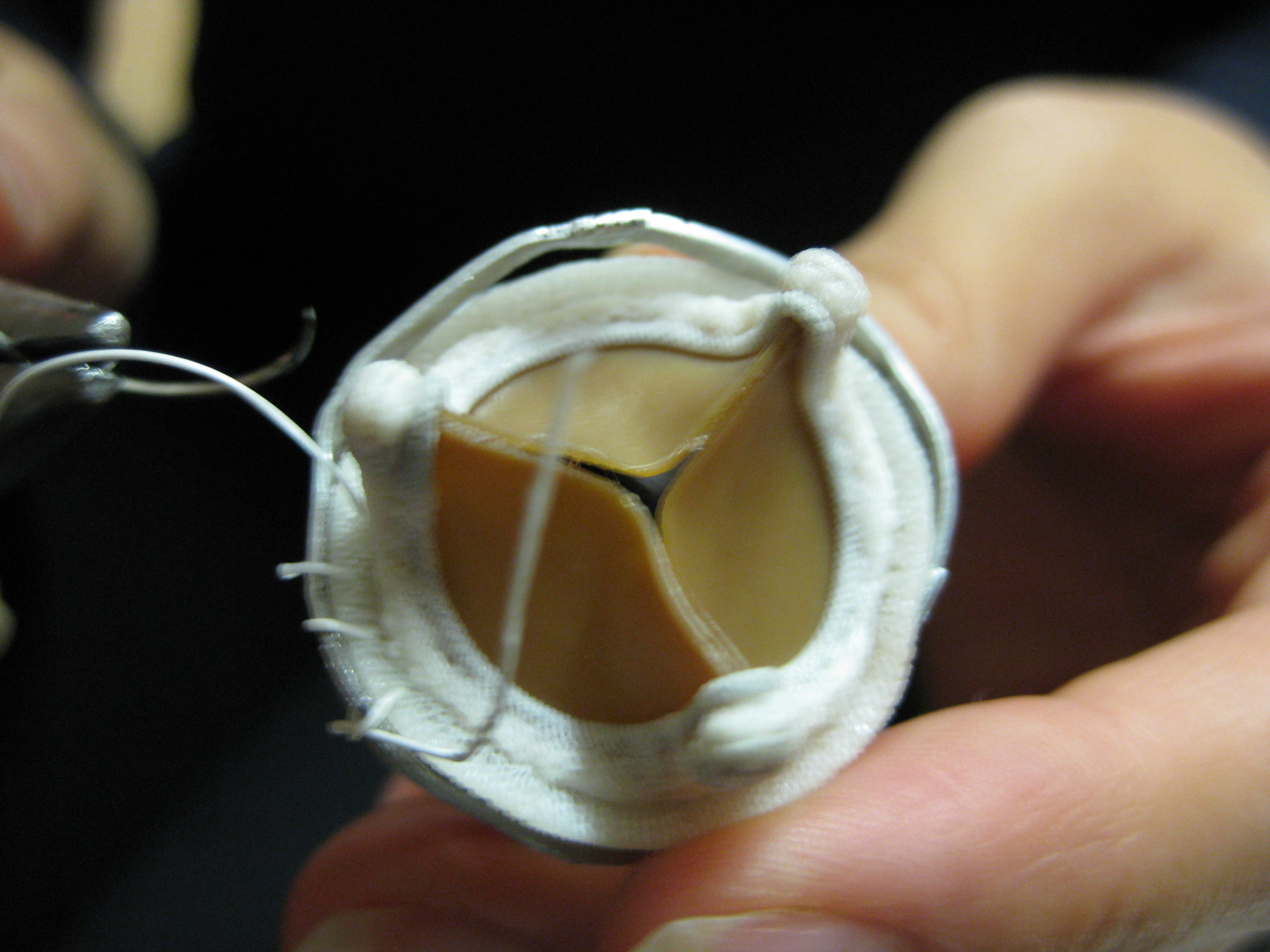

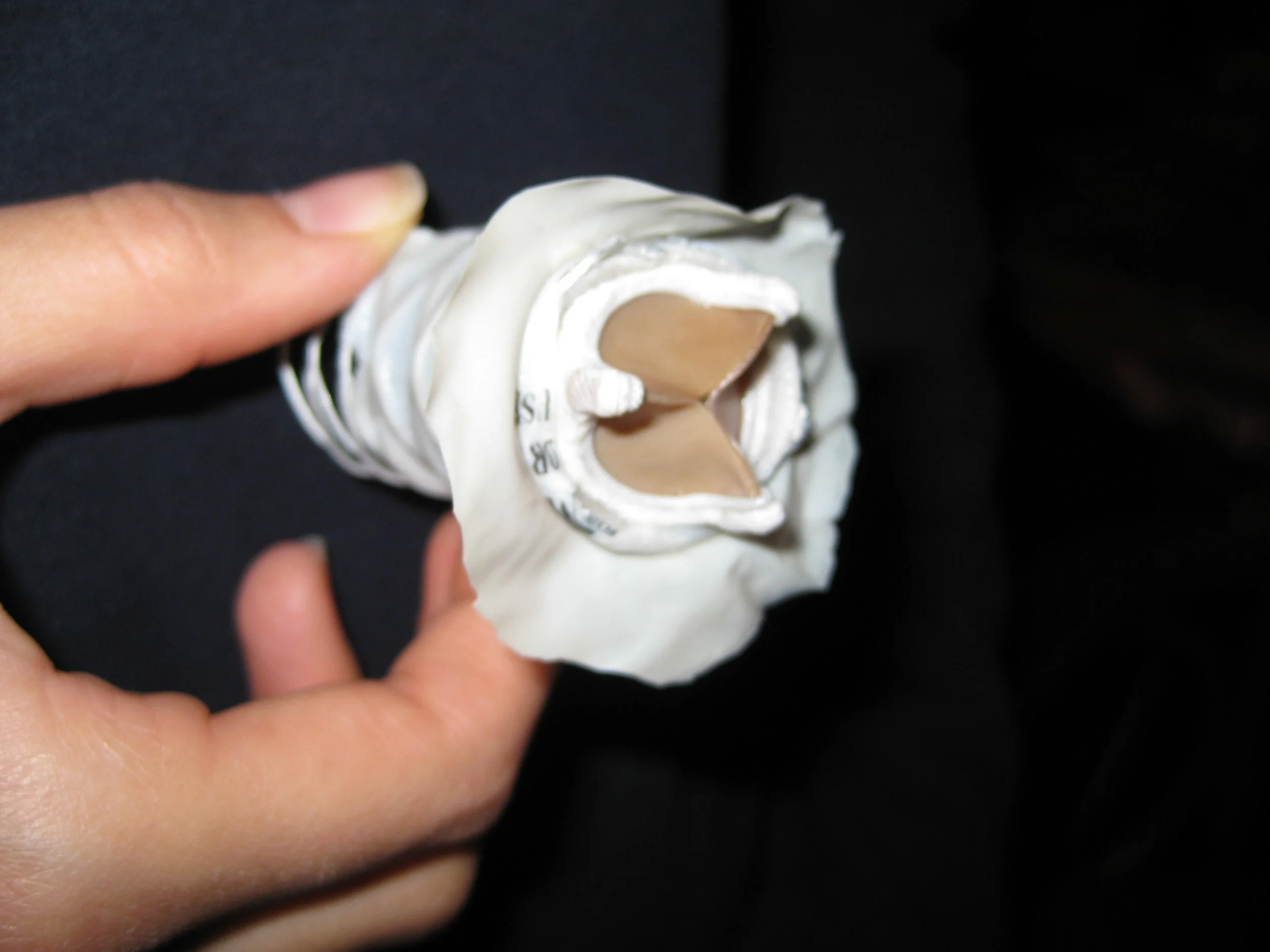

The stent skirt (fig. 1) is the novel component of our product. The advantage of the skirt over current valve technologies is that the skirt seals the top of the valve reducing paravalvular regurgitation. Diastolic flow creates a force against the top of the skirt only increasing the integrity of the seal (fig. 2). During systole, the skirt folds inwards, reducing the tendency for the skirt to act as a parachute therefore reducing the risk of migration (fig. 3).

Skirt will consist of a thin GoreTex rim around the top of the stent body. This rim will be between 3-6 mm wider in diameter than the stent body and be used to seal along the edge of the patient’s calcified aortic valve to prevent paravalvular regurgitation. According to Dr. James Fann, after time in the body the soft compliance of the skirt design will allow the body to form fibrous tissue around the skirt and create a permanent biological seal.

Many different variations of this skirt idea can be prototyped and tested on our stent body. Examples of variations include: Passive Skirt Flap (fig. 4), notched passive skirt flap (fig. 5), passive skirt flap with outer nitinol ring (fig. 6), and an active clamping skirt flap with outer nitinol ring (fig.7).

Stent Body-

Normally, we would use a self-expanding nitinol stent body for our design but because it is not the focus of our design innovation, we will not pursue manufacturing this component. For our prototype we will use a solid material such as delrin to simulate the size and shape of an expanded nitinol stent body and use this as a platform for our skirt iterations. This delrin stent body will be ~2.5 cm tall and have an outer diameter of ~2.5 cm and an inner diameter of ~1.9cm.

3 Leaflet Valve-

Modeled after the proven Perimount RSR Model 2800 19mm diameter 3-leaflet bovine tissue valve.

Prototype: Thin GoreTex leaflets sewn together with GoreTex sutures.